News

News

- what is application of polyacrylamide used for red mud in aluminum plant?

- How does amphoteric polyacrylamide works?

- whats is main applications of amphoteric polyacrylamide?

- what is main applications of nonionic flocculant?

- what is application of polyacrylamide?How is the product classified?what is applications ?

- What are the production processes of polyacrylamide? What are their own characteristics?

- what is PHPA polymer and what is the main applicaitons in oilfeild?

- what is the main application of amphoteric polyacrylamide?

- what is hydrolysis degree and molecular weight ?what is applications of polyacrylamide?

- What are the main factors affecting the viscosity of polyacrylamide?

Polyacrylamide can be used to modify the cement concrete in order to improve its flexural strength, its bond strength and its flexural toughness, and its abrasion resistance has a significant effect, it can reduce the crushing ratio, the permeability and the contractility.

Along with the increase in traffic and overloading phenomenon, the destruction of the pavement and bridge deck pavement is serious, especially some early destruction of bridge deck of transportation departments have paid close attention to, expensive maintenance fee for traffic management departments. Research and development performance and durability of the bridge deck pavement materials, has very important practical significance. Cement concrete has low tensile strength, small ultimate strain and flexural toughness poor, poor permeability, large brittleness and the shortcomings such as craze, thus can meet the special needs of the surfacing layer. A large number of studies have shown that interlayer bonding is not good, poor shrinkage performance and flexural toughness is the main cause of cement concrete bridge deck pavement produces diseases

In order to overcome these shortcomings, people has been seeking ways to improve the performance of cement concrete. In recent years, in adding a small amount of organic polymer cement concrete in cement concrete performance improvement become a new trend. Because organic polymer molecular chain structure and the key section or macromolecular chain segment of spin, determine its nature is different from inorganic non-metallic materials, elasticity and plasticity, so adding a small amount of organic polymer cement concrete, concrete can get high compactness, unapt make the brittleness of concrete increase, in this way, can produce high strength low cement concrete, thereby further expanding the area of the use of cement concrete. In numerous modification in polymer cement concrete, water-soluble polymer acrylamide (Polyacryam ide, PAM) because of their excellent physical and chemical properties, and has been widely applied in various industries. But applying PAM to cement concrete road,By Shandong Shuiheng Chemical Corporation production of polyacrylamide and waterproof concrete, preparation of PAM modified for ordinary waterproof concrete, mixing high efficiency water reducing agent of several kinds of composite material such as waterproof concrete and PAM modified concrete conducted a series of experimental research, and analyses of PAM modified concrete compressive strength, flexural strength, bond strength between the layers, abrasion resistance, infiltration resistance performance, flexural toughness and shrinkage performance and PAM dosage.

1 ratio of raw materials and test methods

1.1 raw material

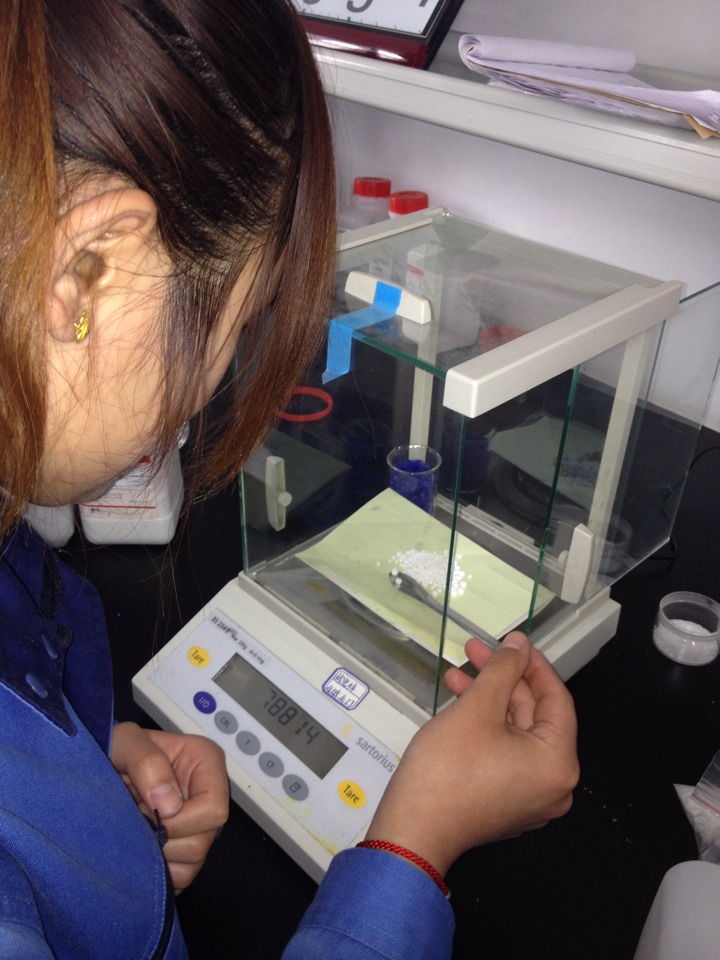

Polyacrylamide: the Shandong Shuiheng Chemical Corporation production of polyacrylamide, white powder dry.

1.2 Mix solution

According to the strength grade of 45C, slump 30 ~ 50 mm and sand ratio 39% waterproof design of ordinary concrete as the benchmark concrete, high efficiency water reducing agent dosage used 1% of the dosage of cement, PAM according to the cement dosage of 6%, 8%, 10% and dosage of 3 kinds of joining in the benchmark in the concrete

1.3 PAM The modified cement concrete mixing process

Due to cement concrete mixer speed is slow compared with net cement slurry mixer (cement concrete mixer speed for 42 r.m in, net and cement slurry mixer speed from 140 to r.m in + / - 5 r.m, in high speed since to 285 r.m in plus or minus 10 r.m in), so the mixing shear rate is low, with the benchmark concrete mixer (3 m) in the same time, the liquidity of PAM modified concrete is bigger, faster, the slump loss false phenomenon of condensation, vibration force or secondary mixing recovered liquidity, liquidity gradually improved and extended mixing time. Found after repeated trial mix and stir the most liquid of 12 m in PAM modified concrete, look and feel is soft than benchmark concrete, continue to extend the time of mixing liquid much improvement, therefore decided to PAM modified concrete mixing with 12 m in time

Cement concrete due to PAM excellent adhesiveness, consistency and adhesiveness increased significantly, even PAM modified concrete has good liquidity, but because of its big viscosity, the slump method cannot measure its slump value, even in the inside of the orifice tube coated with lubricant, also can appear the phenomenon of part of the glue tube, so that the fresh concrete body disturbance caused the slump value distortion measure. Therefore, with a slump to assess its workability is not appropriate

2 Test Results and Analysis

(1) After mixed with 1% high efficiency water reducing agent, the workability of concrete significantly better, water reducing rate of 15%, this is because the after mixed with concrete, the absorption, dispersion, wetting and lubrication of the role of the property; (2) with high efficiency water reducing agent of waterproof concrete strength is obviously enhanced than ordinary waterproof concrete, This is because of the addition of high efficiency water reducing agent, lowered the water cement ratio of concrete, so that the cement stone internal porosity decreased significantly, the structure is more compact, thus significantly higher strength and abrasion resistance.

PAM modified the increase of the permeability resistance of concrete, is in concrete by PAM generated rubber solid compacted fill in concrete pore, thus enhancing the PAM modified the compactness of concrete. Abrasion resistance test also proved it further, PAM modified concrete wear resistance than ordinary waterproof concrete significantly improve, improve the sharpest, But with PAM modified concrete abrasion quantity per unit area increased with increasing dosage of PAM. From the abrasion resistance and seepage resistance, therefore, the optimum content of comprehensive inspection polyacrylamide

PAM modified the flexural toughness of concrete than ordinary waterproof concrete improved obviously, and increased with the increase of dosage of PAM to increase after reduction. its toughness is increased by 169%. This fully shows that the PAM to join, to improve the flexibility of concrete obviously.

3 Summary

Need to choose a low molecular weight, low degree of hydrolysis product, polyacrylamide model:Chinafloc2718 specially used in building materials, putty powder, concrete, bentonite, mortar and the king and some special building materials, it won't react, keep the strength at the same time, and have good liquidity and water retention performance. (1) The addition of PAM, the concrete compressive strength declined, bear the flexural strength, bond strength between the layers, flexural toughness and durability than the base concrete has been a sharp increase, illustrates concrete flexural capacity, bond properties, durability and flexural toughness is improved greatly. The performance determination results available PAM optimal dosage of 8% of the dosage of cement. (2) the brittleness coefficient of PAM modified concrete (crushing ratio) and shrinkage were benchmark concrete is reduced, and decreased with the increase of dosage of PAM. Shows that the brittleness of concrete is reduced, flexible, PAM of brittle narrowed the effect is good. (3) More outstanding is the concrete mixing PAM, the permeability and the interlayer bonding strength exponentially.